| Project title: | Seismic performance of multi-component systems in special risk industrial facilities |

| Funding authorities: | European Union: Seismology and Eartquake Engineering Research |

| Funding code: | H2020-EU.1.4.1.2. – Integrating and opening existing national and regional research infrastructures of European interest |

| Project partners: | Center for Wind and Earthquake Engineering (CWE) University of Trento Depart. of Civil, Env. & Mechanical Engineering School of Civil Engineering National Technical University of Athens (NTUA) Maurer Engineering GmbH University of Belgrade Faculty of Civil Engineering, Serbia Roma Tre University, Department of Engineering Swissnuclear Purdue University, Lyles School of Civil Engineering Wölfel Engineering GmbH + Co. KG (WÖLFEL) |

| Project coordinator: | Prof. Dr.-Ing. Christoph Butenweg Tel: +49 (0) 241 – 60 09 53 16 0 butenweg@lbb.rwth-aachen.de |

| Project duration: | 05.2019 – 05.2020 |

SPIF – 2020 International Blind Prediction Contest

Seismic Performance of multi-component systems in special risk Industrial Facilities

SERA (Seismology and Earthquake Engineering Research Infrastructure Alliance for Europe) Framework

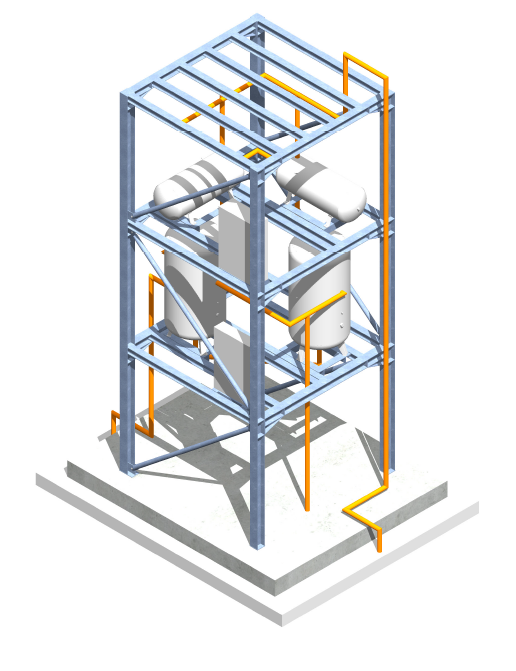

We are pleased to announce the SPIF – 2020 International Blind Prediction Contest of a three-story moment resisting steel frame with vertical and horizontal vessels and cabinets, arranged on the three levels and connected by pipes. The dynamic behaviour of the test structure and installations is investigated by means of shaking table tests at EUCENTRE in Pavia, Italy. The experimental campaign is a part of the SERA (Seismology and Earthquake Engineering Research Infrastructure Alliance for Europe) framework. Please download the following file with all necessary information and instructions:

ZIP-File: SPIF-Blind test prediction-2020

Summary

The objective of the project is the holistic investigation of the seismic behavior of industrial plants equipped with complex process technology by means of shaking table tests. The necessity exists, since past earthquakes have shown that critical interactions can occur in these plants between the supporting structure and plant components, but also between the individual plant components. The structural or process-related interactions can lead to serious secondary damages which, in addition to loss of production, also pose a danger to humans and the environment if hazardous substances are released due to leakages. The proposed structure is a three-storey steel moment frame with vertical and horizontal vessels, arranged on the three levels with some of them connected to each other by pipes. Both firmly anchored and isolated components are taken into account to compare their dynamic behavior and interactions with each other. Furthermore an electrical cabinet and a typical pumping station are installed. The three levels are constructed with flexible diaphragm made of steel gratings. Optional bracing systems are applied to change the stiffness distribution and to cover the effects of eccentricities. Furthermore the effectiveness of two base isolation systems will be investigated. The test structure will be equipped with sensor systems integrated into the test structure for rapid damage assessment applicable for condition analyses or early warning systems. The achieved results on the seismic behavior of multi-component systems with mutual interactions can be used for probabilistic safety analyses in power plants (e.g. nuclear power plants) as well as in industrial plants (e.g. chemical plants). In addition, important findings can be derived for the definition of performance limits, the isolation of structural systems and components and the use of sensor systems for rapid damage assessment. All results can be incorporated into the European standardization process.