Project title: Self-erecting onshore wind turbines with hub height above 120m –

hybrid tower with hoisting device for self-assembly (HYTOWER)

Funding authorities: BMWI – Bundesministerium für Wirtschaft und Energie

IGF – Industrielle Gemeinschaftsforschung

AIF – Arbeitsgemeinschaft industrieller Forschungsvereinigungen

Funding code: IGF-Projekt Nr. 20604 N

Research association: FOSTA – Forschungsvereinigung Stahlanwendung e.V.

Project partners: Institute for Fluid Power Drives and Systems (IFAS), RWTH Aachen

(http://www.ifas.rwth-aachen.de/cms/~pspj/IFAS/?lidx=1)

Chair of Steel and Steel-Composite Construction (STB), Universität Siegen

(https://www.bau.uni-siegen.de/subdomains/stahlbau/)

Project coordinator: Prof. Dr.-Ing. Daniel Pak

(0271) 740 2039

Project duration: 03.2019-02.2021

Project Description:

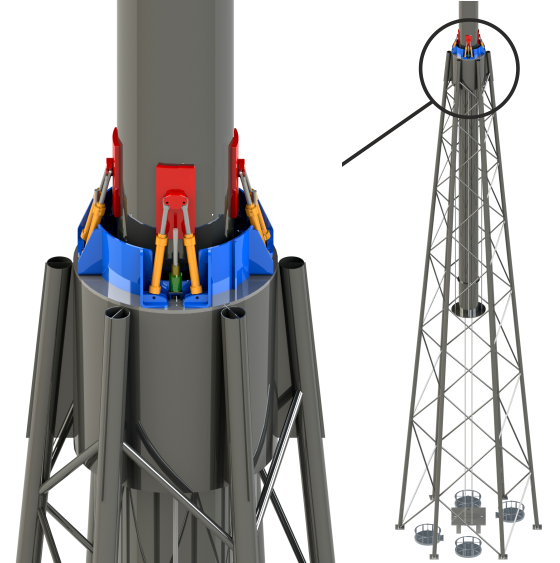

The Renewable Energy Sources Act (EEG) stipulates that renewable energies should cover at least 80 percent of gross electricity consumption by 2050. In recent decades, wind energy has contributed substantially to the required increase in energy yields through larger rotors and increasing hub heights. As a result, the transport limitations of conventional tubular steel towers have been repeatedly reached. An alternative to conventional tubular steel towers are so-called hybrid towers, where the lower segment is erected on-site (e.g., lattice tower), while the upper segment still consists of a tubular steel tower. The construction of high towers through special cranes, however, results in an increase of the main investment costs. Therefore, a reduction of the construction costs should be striven to ensure a positive overall balance.  This research project is aimed at increasing the electricity yields by increasing the turbine’s hub height while reducing the main investment costs through the reduction of construction costs and of the required planning efforts by providing practical design tools, which are achieved by the development of a self-erecting steel tube-lattice-hybrid tower. The research topic is the steel hybrid tower for a wind turbine (approx. dimensions: lattice mast: 120m, steel tube tower: 65m). To reduce the construction costs, the wind turbine is conventionally erected with the help of cranes up to a height of 120 m (lattice tower). The steel tube tower is assembled in parallel inside the lattice tower with a temporary foundation. After completion of the lattice mast the steel tube tower is raised through a cable lifting system to enable the nacelle mounting. Finally, the steel tube tower including nacelle is raised through the cable lifting system to its final position. The horizontal forces, and the bending and torsional moments during the lifting process are supported by hydraulic cylinders located at the transition piece between the lattice mast and tubular steel tower. The implementation of the project results is ensured by the provision of summary guidelines.

This research project is aimed at increasing the electricity yields by increasing the turbine’s hub height while reducing the main investment costs through the reduction of construction costs and of the required planning efforts by providing practical design tools, which are achieved by the development of a self-erecting steel tube-lattice-hybrid tower. The research topic is the steel hybrid tower for a wind turbine (approx. dimensions: lattice mast: 120m, steel tube tower: 65m). To reduce the construction costs, the wind turbine is conventionally erected with the help of cranes up to a height of 120 m (lattice tower). The steel tube tower is assembled in parallel inside the lattice tower with a temporary foundation. After completion of the lattice mast the steel tube tower is raised through a cable lifting system to enable the nacelle mounting. Finally, the steel tube tower including nacelle is raised through the cable lifting system to its final position. The horizontal forces, and the bending and torsional moments during the lifting process are supported by hydraulic cylinders located at the transition piece between the lattice mast and tubular steel tower. The implementation of the project results is ensured by the provision of summary guidelines.

The IGF project “Self-erecting onshore wind turbines with hub height larger than 120m – hybrid tower with hoisting device for self-assembly”, IGF Project No. 20604N, Research association Stahlanwendung e. V. (FOSTA), Sohnstraße 65, 40237 Düsseldorf was funded by the AiF as part of the program for the promotion of industrial joint research (IGF) by the Federal Ministry for Economic Affairs and Energy on the basis of a resolution of the German Bundestag. We would like to express our great appreciation to these organizations for their generous support.