| Project title: | Development of an innovative approach for decoupling infills and non load-bearing masonry walls from the main structure |

| Funding: | Industrielle Gemeinschaftsforschung (IGF), Forschungsnetzwerk Mittelstand |

| Grant number: | Antrag 04306/19 |

| Project partner: | Institut für Ziegelforschung Essen e.V

Center for Wind and Earthquake Engineering |

| Cooperation partners: | Dr. Marko Marinković, Assistant Professor, Chair of Engineering Mechanics and Theory of Structures, University of Belgrade – Faculty of Civil Engineering

Dr. Matija Gams, University of Ljubljana, Faculty of Civil Engineering and Geodetic Engineering, Institute for Structural Engineering, Earthquake Engineering and Construction IT |

| Project project carer: | Prof. Dr.-Ing. Christoph Butenweg (CWE),

Tel: +49 (0) 241 – 60 09 53 16 0 Univ.-Prof. Dr.-Ing. Sven Klinkel (LBB-RWTH) Tel: +49 (0) 241 – 80 25088 |

| Project period: | 01.11.2019-31.03.2022 |

Summary

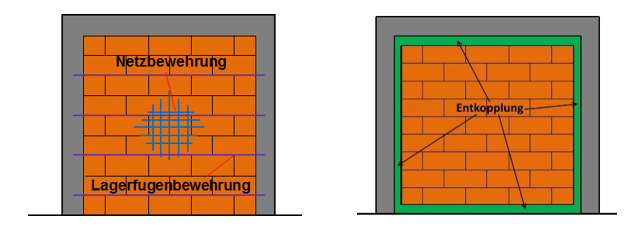

The project`sgoal is to develop innovative decoupling elements for the connection of masonry infills and non-load-bearing partitions to the load-bearing structure to prevent unplanned masonry involvement in load transfer. The decoupling elements are made of recyclable, flexible materials, which are able to absorb relative displacements between the load-bearing structure and the masonry in the direction of the wall due to a special stiffness structure and an optimised design, and at the same time prevent the wall from moving perpendicular to the plane. This represents a paradigm shift as the traditional solution of reinforcing the masonry walls in combination with complex metal brackets is abandoned. Within the framework of the project, the basic materials for the decoupling elements will be first selected and experimentally investigated. Then the design of the decoupling elements is carried out on the basis of computational simulations and the experimental determination of the bearing capacities in small experiments. Subsequently, tests are carried out on infill walls and non-load-bearing partition walls with the installed decoupling systems, which are supplemented by computational parameter studies. Based on the experimental and computational results, design tables and implementation documents are then derived for architects and structural engineers. Upon completion of the project, new innovative and cost-effective decoupling elements will be available to construction practice, which will be delivered to the construction site prefabricated and installed efficiently. The solution can be used by all small and medium-sized brick manufacturing companies in the entire masonry industry, as decoupling can be flexibly applied to all geometries of bricks and materials. The decoupling elements minimise damage under both service loads and high seismic loads.